Education and Understanding the Concept of Reservation

In a recent development, reservation in job promotions has been stated as not being a fundamental right. This topic has stirred quite a debate, with many feeling that it undermines the principle of equal opportunity. The decision questions the balance between meritocracy and affirmative action in professional environments. As a blogger, I find this issue intriguing and worthy of further exploration. It's crucial to ensure that we are not compromising the essence of fairness while striving for diversity and inclusion.

Read moreWhy is The New York Times so critical of India?

Alrighty folks, let's venture into this spicy topic. Ever wondered why the New York Times seems to have a grudge against India? It's like they're playing a game of "Whose Country Can We Criticize More?" and India's their favorite contestant! Some say it's about political bias, others argue it's due to their Western perspective. Bottom line, it's a complex soup of factors, but the flavor sure seems to lean towards the 'critical of India' side!

Read moreDo you hate Indian news channels?

As a viewer, I've been observing Indian news channels and it's clear there's a growing sentiment of dissatisfaction among the audience. The excessive sensationalism, lack of objective reporting, and incessant debates often overshadow the actual news. The intertwined relationship between politics and media also influences the content, raising questions about the credibility of these channels. While it would be unfair to say I hate them, it’s definitely disheartening to see the current state of affairs. I believe there’s an urgent need for reform to reclaim the essence of true journalism.

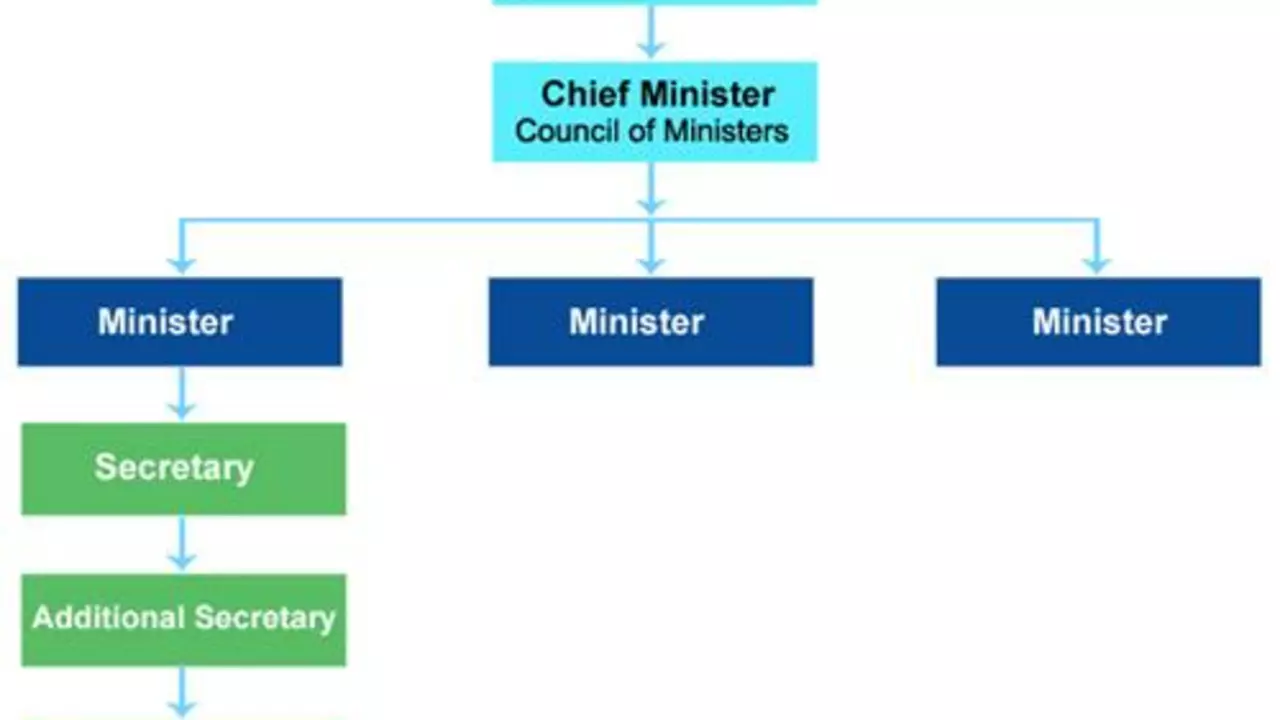

Read moreWhat are the various Ministries under the Government of India?

The Indian government is organized into numerous ministries, each overseeing a specific sector of public policy, government function, or economy. Key ministries include Finance, Defence, Home Affairs, External Affairs, and Human Resource Development, among others. Each ministry is headed by a minister who is a member of the Union Cabinet, and they are responsible for formulating and administering the rules and regulations and laws relating to their designated area. The ministries play a fundamental role in the functioning and governance of India, ensuring smooth operation across all sectors. The number and nature of ministries are subject to change based on the policies and priorities of the ruling party.

Read moreBSF permits fishing on Indian side of Padma from today?

Great news for our local fishermen - the Border Security Force (BSF) has given the green light for fishing on the Indian side of the Padma river, starting today. This decision comes as a huge relief for our fishing community who greatly rely on this for their livelihood. The restrictions were initially imposed due to security reasons. As I understand, the permission was granted after a thorough security assessment. So, grab your fishing rods and let's support our local fishermen, their fresh catches are back on the market!

Read moreDo Indians eat too much?

In my recent exploration of the topic "Do Indians eat too much?", I've discovered various opinions and studies on Indian eating habits. While some argue that Indians consume larger portions and high-calorie diets, others believe that the diversity in Indian cuisine balances out the nutrition. It's crucial to remember that India is a vast country with diverse food habits, so generalizing the entire population's eating habits might not be accurate. In my opinion, it's important to focus on maintaining a healthy lifestyle and making informed choices when it comes to food. So, let's not label an entire nation, but rather encourage mindful eating and a balanced diet.

Read moreDo one needs a marriage certificate to get passport in India?

As an Indian citizen, I've often wondered if a marriage certificate is required to obtain a passport in India. After conducting some research, I've found that it is not mandatory to provide a marriage certificate for a passport application. However, if you wish to include your spouse's name on your passport, then a marriage certificate is necessary. Additionally, if you are applying for a dependent visa, the marriage certificate becomes essential. Overall, a marriage certificate is not a compulsory document for a passport, but it can be useful in certain situations.

Read moreWhat are typical problems for getting government jobs in India?

Government jobs in India can be challenging to obtain. Many people face problems such as high competition, limited vacancies, bureaucracy, and the need for high qualifications. Additionally, the selection process is often lengthy and requires multiple rounds of assessment. Furthermore, corruption and favoritism can also play a role in selecting applicants. To increase the chances of success, candidates should stay informed about the latest job vacancies, prepare thoroughly for the selection process, and build professional networks.

Read moreWhat are the online sites to find jobs in the Netherlands?

Looking for a job in the Netherlands? There are a variety of online sites to help you find the perfect position. From platforms specializing in Dutch jobs to multinational websites, you can find a range of options to help you get started. Job boards such as Indeed, Monster, and Stepstone are great for finding Dutch job postings. Additionally, many of the larger international companies have their own recruitment websites. Social media networks like LinkedIn and Twitter also offer job postings and great networking opportunities. Finally, don't forget to check out professional and industry-specific websites which can offer more specialized positions. No matter what type of job you are looking for, there are plenty of online sites to help you find it!

Read moreWho is the best life skill coach in Delhi NCR?

The article discusses who the best life skill coach in Delhi NCR is. It examines various life skill coaches in the region, taking into account their qualifications, experience, and the type of coaching they offer. The article concludes that the best life skill coach in Delhi NCR is Abhishek Sharma, who has over 15 years of experience in the field and provides a variety of life skill coaching services. He is also recognized by the International Coaching Federation and is considered to be an expert in his field. Abhishek Sharma is highly recommended for anyone looking for a life skill coach in Delhi NCR.

Read more